How To Add Windows Into New Walls

Installing a Window in a Blank Wall

Who in their right heed would cut a giant pigsty in the side of a make new house?

This was peradventure one of the more than gut wrenching projects I take taken on (and I'thousand the ane that built the house). The stairwell that leads to our basement never had a window in information technology and that entire side of the house was e'er dark as a result. The basement, mudroom and stairwell ever needed to have the lights on when in use. Afterward walking by it one solar day, I said to Jamie, "Why didn't we put a window in that wall?" And the rest was history.

That being said, now I had to figure out how to put a window in that wall. Check out the full project video below and read on to see the step by stride procedure of united states actually doing it.

Disclosure: This projection is sponsored by DAP Products and The Abode Depot. Both brands are amazing and support our community of Doers.

Time needed:3 days.

The steps below outline how nosotros cut a pigsty in a blank exterior wall and installed a massive picture window. Equally ever, contact your local building officials how to proceed with whatever structural changes to your dwelling house.

- Laying out the Window Size

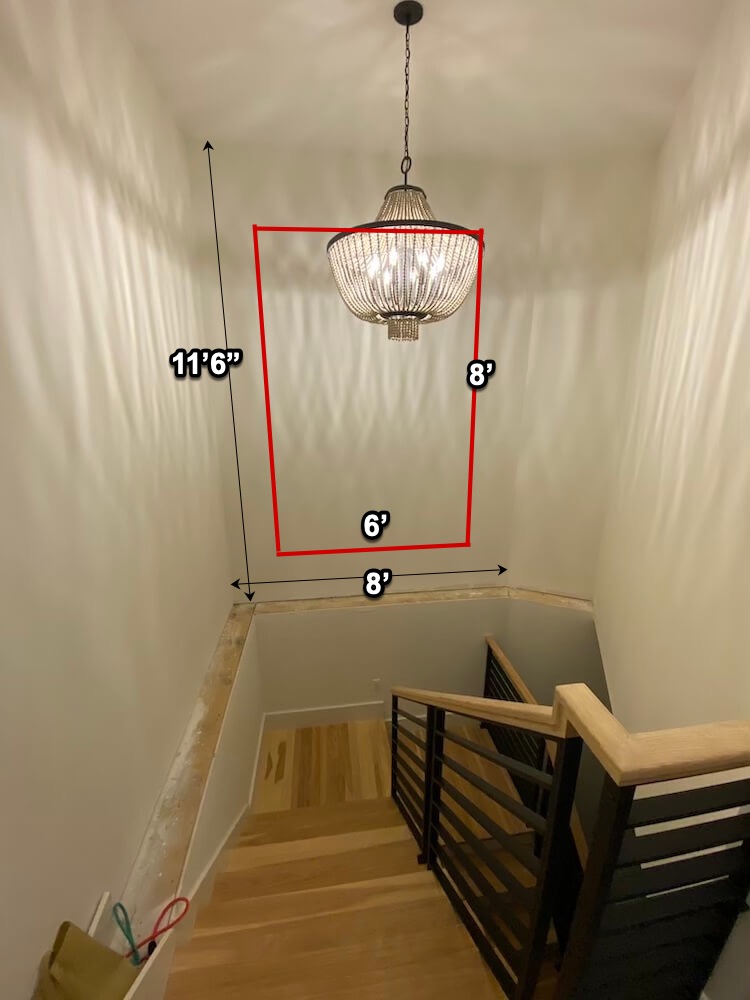

When I was deciding on the window size, we wanted to go large while still leaving enough room for the header and surrounding framing. Ultimately nosotros decided on a 6′ wide by viii′ tall picture window to let a massive amount of low-cal in.

- Shopping for the Window

Rather than shopping online, we new we needed to head into the millworks department at our local Domicile Depot to chat with an good. After talking through all our options we settled on an Andersen 400 series motion-picture show window.

- Cutting Away the Drywall

After receiving our window we could become started on the actual installation. This begins by laying out the overall hole with a pencil. This includes the rough opening, framing and access to structure we needed to tie into. And then we set upwards plastic sheeting to contain the dust and I advisedly cut the drywall and removed information technology from the area.

- Removing the Insulation

With the opening cutting we removed the insulation from the area we would be working in. Luckily there was no electrical in the wall, otherwise we would take had to relocate that.

- Supporting the Surface area

When cutting out the studs from an exterior wall, the weight of the roof can cause the height plate to deflect and creating a trouble during header installation. To prevent this I assembled an I-beam with 2x6s and wedged 2x4s nether it to temporarily back up the weight.

- Cutting the Studs Out

Later marking the expanse of the studs that would need to exist removed, I made cuts at the pinnacle and bottom of that area as close to 90 degrees equally possible. To free the studs from the sheathing I and then cut the nails between the studs and sheathing with a reciprocating saw.

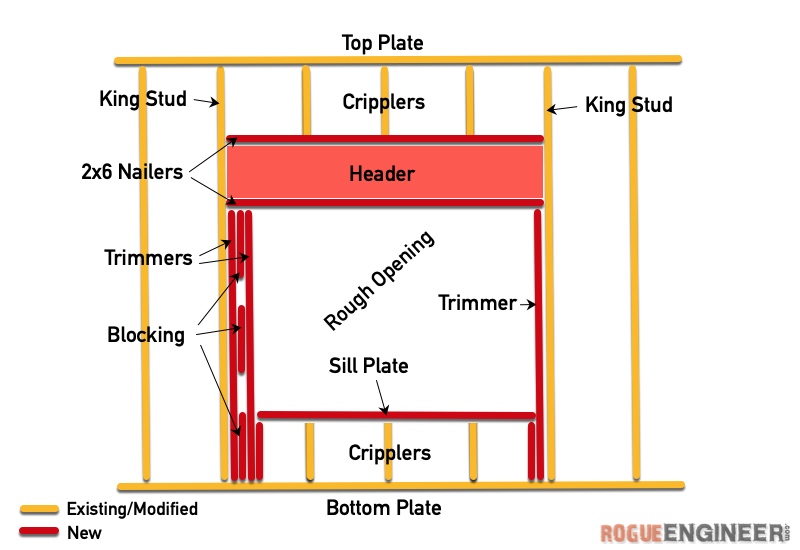

- Framing the Crude Opening

Below I put together a diagram of the framing that needed to be added to support the weight of the roof. This design is for a 2×half-dozen outside wall. If you have a 2×four wall, the header may not need the 2×6 nailers higher up and below.

We started by screwing the top 2×6 nailer to the cripplers. We and so used a straight edge to brand sure it was completely apartment and shim the joints that were not.

Then I installed the trimmers and blocking to get usa to the final rough opening width. The trimmers are cut to allow for the header to sit down snugly on top.

For our span nosotros determined that ii 9-i/4″ laminated beams that go nailed together with 4 nails every sixteen″ would exist more than sufficient. Always refer to your local codes and guidelines when attempting a project like this.

The lower nailer gets nailed to the bottom of the header and slid into place. Luckily we got information technology right the offset time and it fit perfectly.

Next nosotros measured down from the header to locate the exact height of our sill plate. Nosotros installed the boosted cripplers on each side, insulated as much as possible, and then installed the sill plate.

- Cutting the Pigsty

This is a big moment…

It's much easier to cut the pigsty from the outside, so to locate the rough opening I drilled a hole in each corner.

So I used a chalk line to mark the rough opening on the exterior and cut it out with a reciprocating saw.

Nosotros concluded cutting information technology in ii pieces because of the weight and handling.

- Flashing the Sill

To brand sure any water that gets backside the window flange does non penetrate the sill, nosotros needed to flash that prior to the window being set. I started by installing a beveled siding board on the sill. This volition give a slight pitch that volition direct the water to the outside.

Then I applied flashing tape to the sill and about a human foot or so up the sides. I used ZIP'due south stretch tape because the corners can exist formed into place with just one piece of tape.

Then we applied a bedding of DAP three.0 (non-waterbased sealant). This is a large bead of sealant that is practical around the sides and top and into the back of the flashed sill. This volition act as an adhered gasket and forbid water from getting past it.

- Setting the Window

This window is big… and heavy. 406 pounds to exist exact. Then we used moving straps and as many abled bodies equally we could to hoist it on a bench that would serve as a staging area then the last motion to the rough opening.

Once nosotros were able to confirm that it was plumb, level and foursquare, we then nailed it into place with 2″ covering nails. These nails take a very apartment and large head that volition be easy to install outside trim over.

- Flashing the Sides and Top

Flashing tape and so gets installed over the sides of the nail flange and then the top to create a shingled layering of flashing.

- Insulating

To seal around the window nosotros used Impact 'n Foam's No Warp Cream which volition ensure the foam does not expand too much and crusade the window frame to bow.

I then cut a slice of ii″ thick rigid foam board insulation to fill the header cavity. While the remaining space around the rough opening gets batts insulation.

- Drywall

My least favorite role. I cut the drywall to make full all the voids effectually the window and screwed them in place with drywall screws.

When drywalling, to blend the seam of two pieces of drywall you demand to use joint compound.

Luckily my father-in-constabulary strolled in at just the right time and I was able to con him into taking over. First he applied the drywall tape over the seams, using the joint compound to fill the joints. The record is important. That's where you get the force.

After that drys, the finish coat can be applied with a larger, viii″ drywall knife.

Once that dries, the joints can go sanded and painted to match.

- Installing Trim

We matched the remainder of the firm with 1×4 vertical trim and five/4×vi horizontal trim that overhangs the sides by one/2″. To save some endeavor the trim was painted prior to install.

Later on the trim was installed nosotros followed up with DAP's Farthermost Stretch crackproof caulk and filled the blast holes with DAP Premium Forest Filler.

With the window caulked into the wall and the nail holes filled we could then apply a final glaze of paint to the trim.

- Exterior Siding and Sealing

To trim the window, I matched the rest of the outside with a 5/4×half dozen picture frame and filled in the batten strips.

After the trim was installed Jamie filled the nail holes with DAP Platinum Patch which an exterior grade filler, suitable for all types of surfaces.

She and so applied a bead of DAP DynaFlex Ultra all the manner around the exterior trim and a bead of clear betwixt the window and the trim. This is a not bad option for exterior caulk because of its lifetime resistance to mold and mildew, crackproof bond and easy water clean up.

With all the caulk and filler dried she then moved onto painting the exterior trim and blending it all into the existing siding.

And then there ya have it, a new, massive window, installed in a solar day. Drywalled, trimmed and painted the post-obit two days.

Information technology was an oversight, not putting a window in thus wall when building the firm, but totally worth the attempt to practise then after the fact. It lets so much natural light into a infinite that had none before. The mudroom use to be dark but now gets tons of light all day.

This side of the basement was always dark simply now is filled with light in the afternoons. If you want to learn more about how the stairs and railing from 50.J. Smith Stair Systems went in, bank check out our Dream House episode 10.

If you consider taking on a project similar this, I would love to come across how it turns out in the comments! Otherwise, thanks for reading and every bit e'er, be prophylactic and happy building.

About The Writer

Related Posts

How To Add Windows Into New Walls,

Source: https://rogueengineer.com/installing-a-window-in-a-blank-wall/

Posted by: newmanmunly1988.blogspot.com

0 Response to "How To Add Windows Into New Walls"

Post a Comment